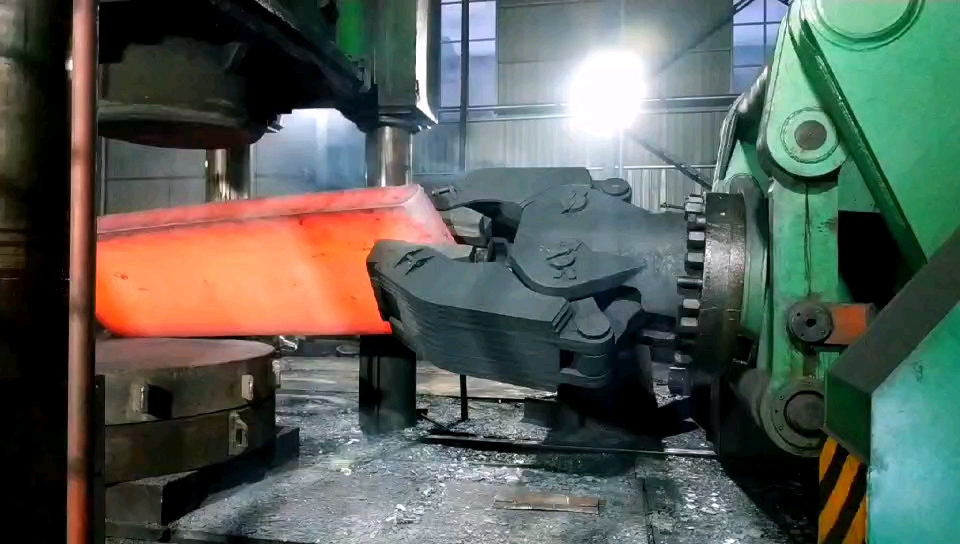

Free forging

Free forging is usually performed between two flat dies or patterns that do not have a die cavity. The tools used in freeforging are simple in shape, highly flexible, with short cycle times and low costs. Although the labor intensity is high, the operation is difficult, the productivity is low, the quality of the forging is low, and the machining allowance is large. Therefore, it is only suitable for the situation that there are no special requirements for the performance of parts and the number of parts is small. For large forgings, free forging is mainly used in the wool manufacturing process. In the open forging process, the blank can be forged into a stepped bar, or the blank can be made into a simple shape such as a round cake shape and a rectangle by upsetting or flattening.

Open die forging (burr die forging)

The blank between the two modules is deformed, and the general part is limited to the mold cavity. Excess metal flows out of the narrow interlayer between the two dies, creating burrs around the forging. Under the resistance of the mold and surrounding burrs, the metal is forced to compress into the shape of the mold cavity.

Closed die forging (also known as burr-free die forging)

During closed die swaging, the direction of movement of the die is not perpendicular to the horizontal edge. The cavity of closed die forging has two functions; One part is used for the formation of wool return, and the other part is used for guiding.

Extrusion die forging

There are two types of extrusion die forging: forward extrusion die forging and reverse extrusion die forging. Extrusion die forging can be made into various titanium rings. Forgings with higher geometric dimensional accuracy and denser internal structures can be manufactured. A perforated punch creates pressure at the center of the metal cavity to make the metal flow outward to achieve the effect of filling the cavity. Generally, there is no burr on the parting line of forgings.

Part of the die forging

In order to forge large integral die forgings on existing hydraulic presses, segmented die forging processes such as segmented die forging and backing plate die forging can be adopted. Some die forging methods are characterized by segmented processing of titanium cakes. The tonnage of equipment required can be small for one part at a time. Generally speaking, this method can process large forgings on medium-sized hydraulic presses.

Isothermal die forging process

Before forging, the mold is heated to the blank forging temperature, and the mold is kept consistent with the blank temperature during the whole mold forging process, and the large deformation is achieved under the action of small deformation force. Isothermal die forging is very similar to isothermal superplastic mold forging. The difference is that the latter must be superplasticized before forging the die so that it has small shaft grains.